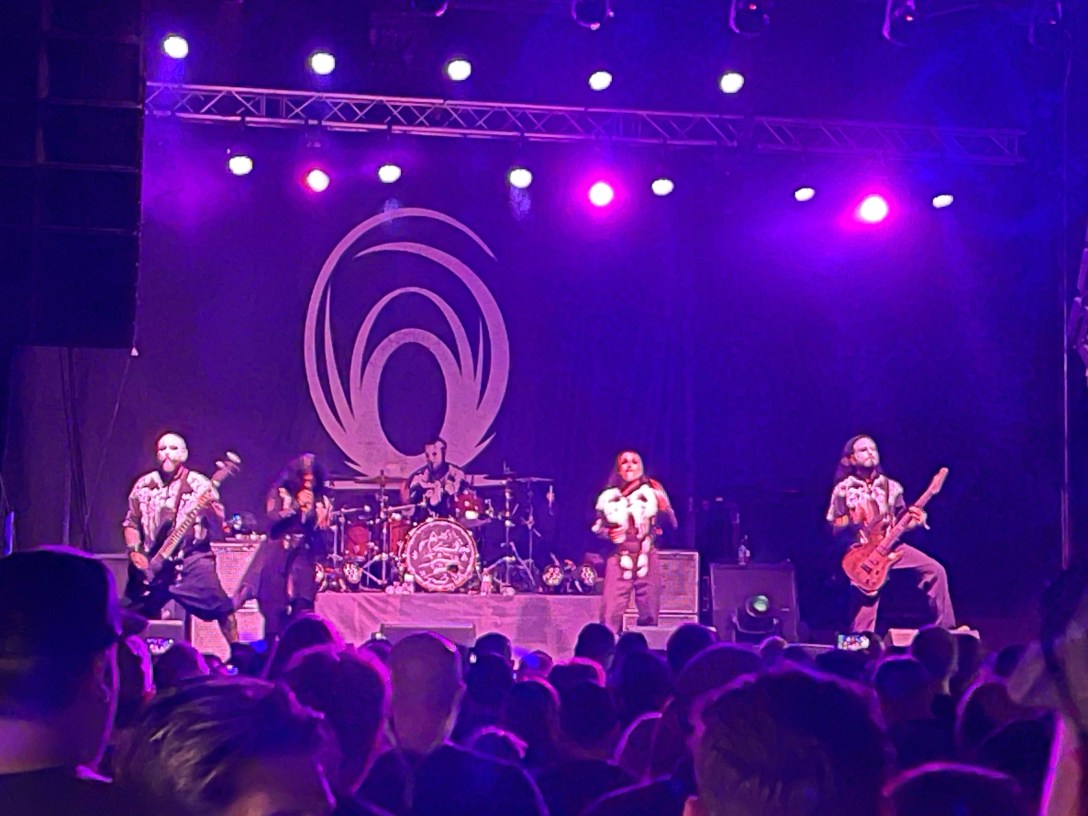

Quick, name the band in the feature image!

You can read the first two posts in this set by following these links: Part 1, Part 2.

So I had my parts ordered. Body wood from Maderas Barber, neck wood from Exotic Wood Zone, the tuner/bridge from hipshot, pickups from lace, and the potentiometers and capacitors and wiring from amazon. But in the in-between time I wanted to get some tests in to make sure my model was viable and make any small tweaks before running my CNC machine over the expensive woods.

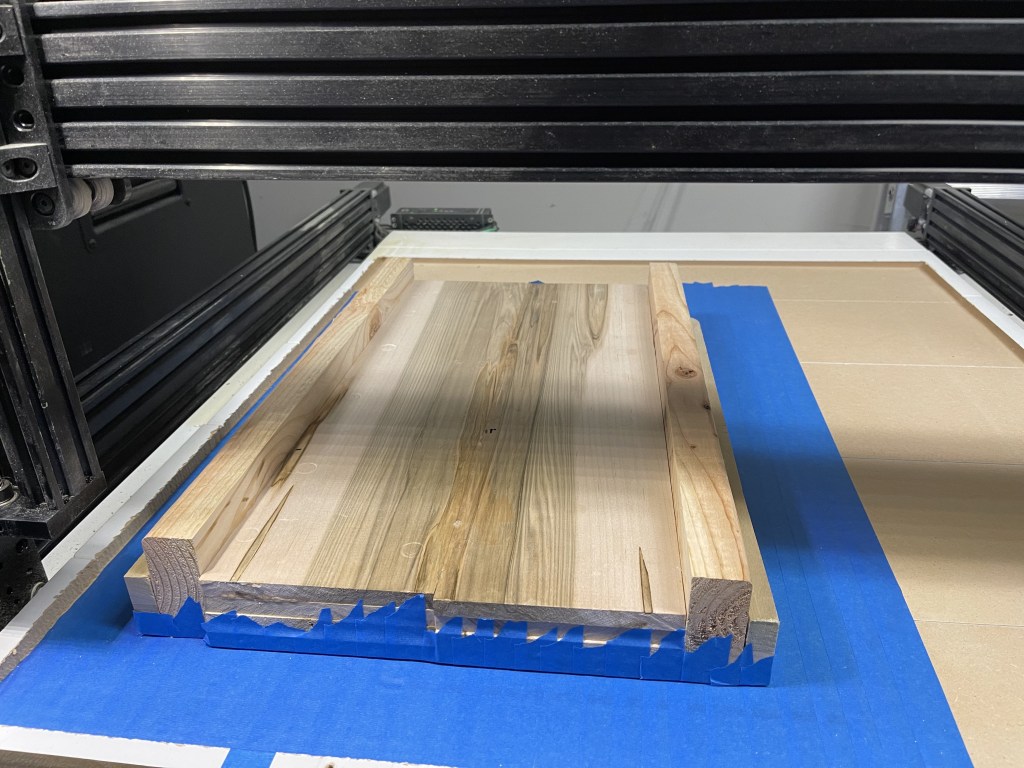

I made a trip down to Lowes and picked up some cheaper wood to work with. A piece of poplar that looked big enough to cut the neck out of and some oak that I could cut & glue into the same size as the body wood I was expecting.As you can see in the picture I kind of suck at estimating sizes and had to add some extra wood to the ends.

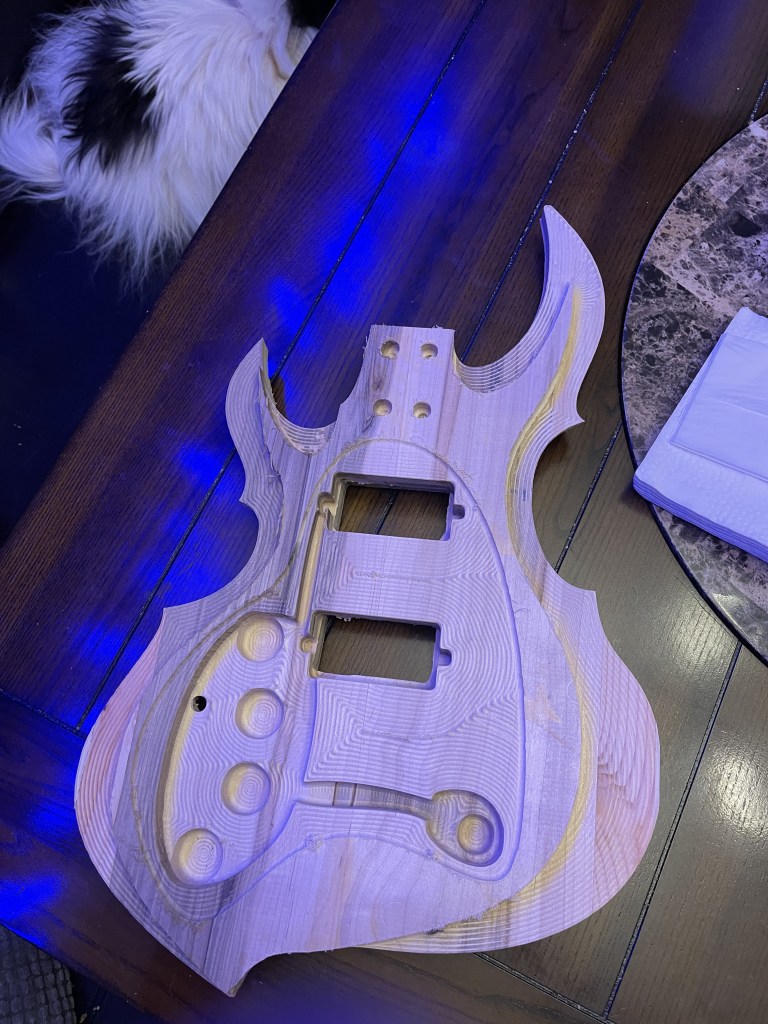

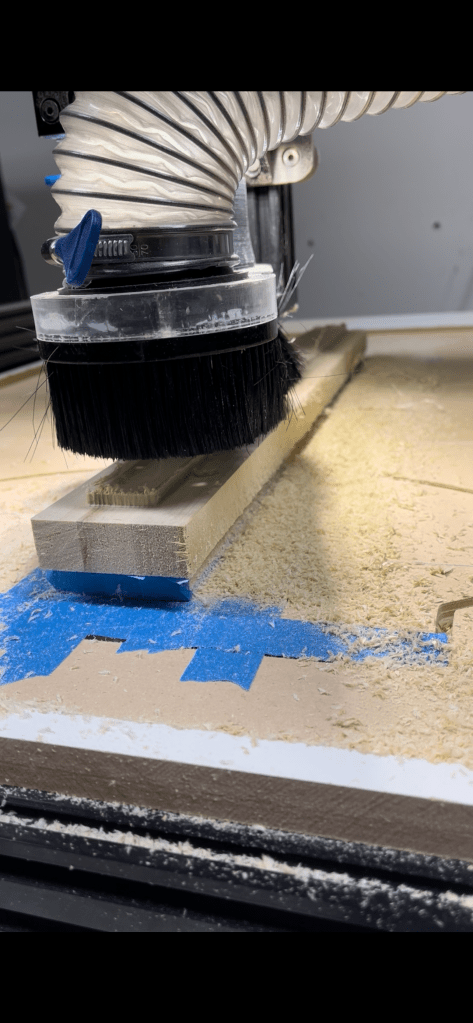

I didn’t want to cut too agressively because I wouldn’t dare risk cutting super agressively with the wood I’d actually be using. That meant the cutting took forever. Seriously. 3 or 4 days running from about 9:00 A.M. to 10:00 P.M. First lesson I learned in this test: Getting a good alignment on side 1 and side 2 of a two sided routing is a lot more complex than just squaring up along the bottom of the wood. There were small differences in side 1 and side 2 of the wood along the edge that cause me some frustrations. I decided that in the future I would use dowels in holes drilled through the wood and into the table in the center of the wood to assist in aligning the top & bottom. Still, I was only off by about a milimeter in each direction, something that could be sanded out.

Second lesson, milling only part way on one side and the rest of the way on the other alleviates concerns about collisions between the router and wood. And this is why we do tests before.

It was thrilling to see my model as a physical thing.

Next I ran a test on the neck. This time things were much more frustrating. I tried the dowel in the hole thing, but my holes were not tight enough on the dowel, so there was some sliding as I was setting the part down on the table. Secondly, I had not realized my tram had gone out of square, so as the head moved further back on the table, it was moving more to the right. So when both sides were done, the offset had doubled and left me with a frustrating puzzle to figure out.

If you’re wondering about all the painter’s tape, it’s a trick I learned by watching the openbuilds videos. With a clean surface you put the tape down on your bed, a bit bigger than your stock. Same thing with the underside of the stock. Then you superglue the two sets of tape together. Then you let the glue cure, it only takes a few minutes or so, and you can use accelerant that makes it almost instant. Now you have secured your stock to the table but are able to remove the superglue via tape and have a clean bottom to your wood. But you need to make sure that: 1. You have the tape on the table covering enough area to resist the pressure of your routing bit moving horizontally through the stock; 2. You have enough surface area on the bottom of your stock to hold it down and resist the forces trying to push it around. Nothing in this project has been a problem with that second consideration, but I had a couple of catastrophic failures because of the first one.

While the body was being cut, I received some deliveries, the amazon orders and –

Nice, right? I couldn’t wait to try them out, but since I didn’t really have a way to test them I’d have to. As soon as the body was done, first thing I did was try to sit these puppies in the holes for the pickups aaand, they didn’t fit. The holes on the body were too small, so I had to wait for payday to head down to Lowes and get a rasp. Sandpaper was going to be be ridiculous to clear the holes out.

Anyway, I’m going to end this post there. Because after pulling the body off the cnc router, the long slog of hand shaping the wood began and that’s a whole post of its own.

And the band at the top of the post? It’s Lacuna Coil. I’ve loved their music forever and happened to see that they were going to be playing while I was at another concert (Skinny Puppy, another awesome show if you get a chance to go). So glad I got to see them. Great, loud music, and the show is full of energy. The band hung out outside after the show, chatting with everyone. No stupid extra fee for vip access in an awkward, one sided meeting. They really do seem to love their fans.

Well, type to ya next time.

[…] can follow the journey so far by following these links: Part 1, Part 2, Part 3. I’d also like to point out that I’ve managed to stick to this project for almost 8 […]

LikeLike